Issue No. 153

- Contents

- 1) WEN025664D-CTP – 5.5 inch OLED with PCB & Capacitive Touch

- 2) WEA160128A – 1.92 inch OLED with PCB

- 3) Enhance the lifetime of OLED by protecting from UV damage

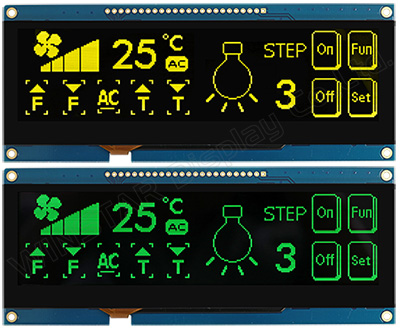

WEN025664D-CTP –5.5 inch OLED with PCB & Capacitive Touch

WEN025664D-CTP model is an industrial grade 5.5-inch COF Graphic OLED with frame bezel and Capacitive Touchscreen, made of resolution 256x64 dots. This OLED module is built-in with SSD1322 COF IC; it supports 6800/8080 8-bit parallel, and 3-wire/4-wire SPI interface, supports 16 (4-bit) gray scale, supply voltage for logic 3V, the display current with 50% checkerboard is 240mA @3.0V VDD (typical value), 1/64 driving duty. This model is having Capacitive Touchscreen on module; it is built-in with GT911 IC which supports I2C interface, one detect point for CTP, normal glare surface glass. The module is having PCB on module which is suitable for customers to use wire connection; customers do not need to develop extra PCB for their applications. Also, we integrated VCC circuit on PCB to make it easier for customers to use. This module is also supporting many wiring methods like PIN, FFC, CN, FPC.

There are four mounting holes on PCB board which is an easy method for customers to fix modules on their applications. This OLED module is suitable for smart home application, medical device, industrial control, etc. WEN025664D-CTP model can be operating at temperatures from -20°C to +70°C; its storage temperatures range from -30°C to +80°C.

|

|

► Link to WEN025664D-CTP web page

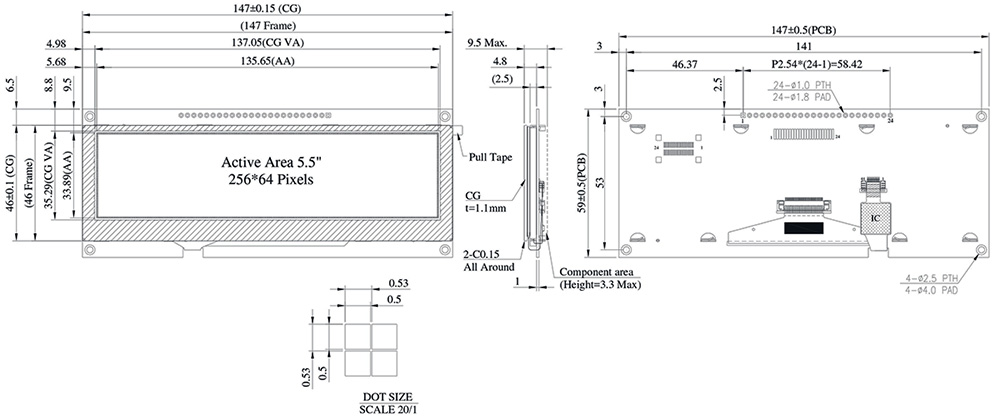

WEA160128A – 1.92 inch OLED with PCB

WEA160128A model is the extension item of WEO160128A which is having a PCB board on module; it’s diagonal size 1.92 inch, made of 160x128 pixels. This PCB board with four mounting holes is an easy method for customers to fix modules on their applications. WEA160128A OLED module is built in with SH1108 IC; it supports 4-wire SPI interface, 1/128 driving duty, supply voltage for logic is 3V, the display current with 50% checkerboard is 100 mA @3.0 VDD (typical value). The module is having a PCB board on module which is suitable for customers to use wire connection; customers do not need to develop extra PCB for their applications. The module provides a standard metal PIN (2.54mm pin hole) for customer to connect to the product. The PCB has been designed with a boost circuit, and customers only need to provide a set of VDD voltage to use.

This OLED module is suitable for smart home application, medical device, smart control, meter, etc. WEA160128A module can be operating at temperatures from -40°C to +80°C; its storage temperatures range from -40°C to +85°C.

|

|

Enhance the lifetime of OLED by protecting from UV damage

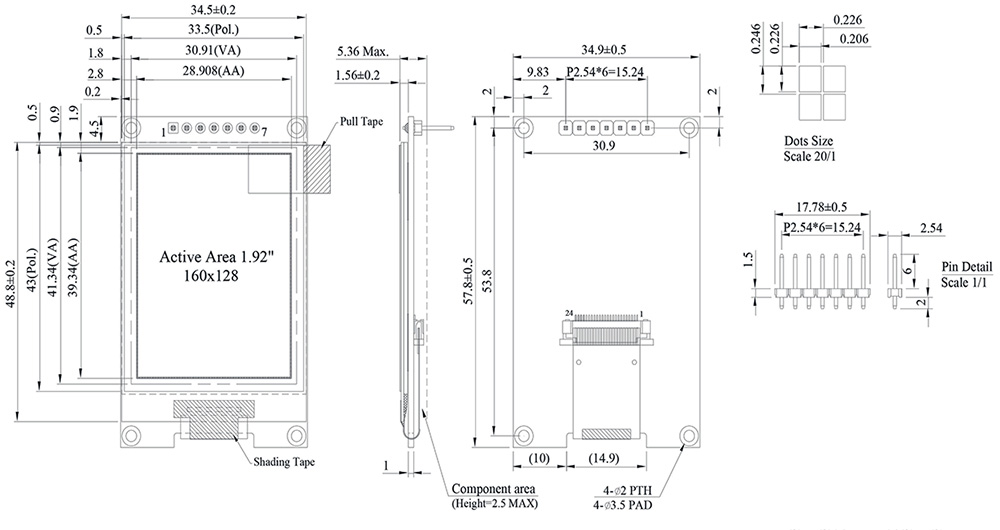

The Ultra-violet (UV) light has a shorter wavelength and greater energy (refer Figure 1) than visible light. If human beings expose to high-intensity UV light, it will lead to body damaged. Also, organic materials in OLED displays may be suffered by UV damage.

It is common to use UV index to define the intensity of UV, which is an international standard measurement of the strength of the sunburn-producing ultraviolet (UV) radiation at a particular place and time. Please refer Chart.1

| UV index | Media graphic color | Risk of harm from unprotected sun exposure, for the average adult | Recommended protection |

|---|---|---|---|

| 0 to 2 | Green | "Low" | A UV index reading of 0 to 2 means low danger from the Sun's UV rays for the average person. Wear sunglasses on bright days. If you burn easily, cover up and use broad spectrum SPF 15+ sunscreen. Bright surfaces, sand, water, and snow, will increase UV exposure. |

| 3 to 5 | Yellow | "Moderate" | A UV index reading of 3 to 5 means moderate risk of harm from unprotected sun exposure. Stay in shade near midday when the Sun is strongest. If outdoors, wear sun-protective clothing, a wide-brimmed hat, and UV-blocking sunglasses. Generously apply broad spectrum SPF 15+ sunscreen every 1.5 hours, even on cloudy days, and after swimming or sweating. Bright surfaces, such as sand, water, and snow, will increase UV exposure. |

| 6 to 7 | Orange | "High" | A UV index reading of 6 to 7 means high risk of harm from unprotected sun exposure. Protection against skin and eye damage is needed. Reduce time in the sun between 10 a.m. and 4 p.m. If outdoors, seek shade and wear sun-protective clothing, a wide-brimmed hat, and UV-blocking sunglasses. Generously apply broad spectrum SPF 15+ sunscreen every 1.5 hours, even on cloudy days, and after swimming or sweating. Bright surfaces, such as sand, water, and snow, will increase UV exposure. |

| 8 to 10 | Red | "Very high" | A UV index reading of 8 to 10 means very high risk of harm from unprotected sun exposure. Take extra precautions because unprotected skin and eyes will be damaged and can burn quickly. Minimize sun exposure between 10 a.m. and 4 p.m. If outdoors, seek shade and wear sun-protective clothing, a wide-brimmed hat, and UV-blocking sunglasses. Generously apply broad spectrum SPF 15+ sunscreen every 1.5 hours, even on cloudy days, and after swimming or sweating. Bright surfaces, such as sand, water, and snow, will increase UV exposure. |

| 11+ | Violet | "Extreme" | A UV index reading of 11 or more means extreme risk of harm from unprotected sun exposure. Take all precautions because unprotected skin and eyes can burn in minutes. Try to avoid sun exposure between 10 a.m. and 4 p.m. If outdoors, seek shade and wear sun-protective clothing, a wide-brimmed hat, and UV-blocking sunglasses. Generously apply broad spectrum SPF 15+ sunscreen every 1.5 hours, even on cloudy days, and after swimming or sweating. Bright surfaces, such as sand, water, and snow, will increase UV exposure. |

The emitting layer made by organic material is the key factor behind the light emission of OLED displays. High-intensity energy will damage the structure of organic material in the emissive layer, which causes low light-emitting efficiency and fast brightness decay.

In order to protect the organic material from UV damage, we have to minimize the intensity of UV wavelength. Meanwhile, we don’t want to decrease the intensity in the visible light range(400nm~700nm). For this purpose, add a polarizer which the transmission of wavelength < 380 um (UV band) is under 1% is a very suitable solution. Please refer Figure.2.

![[Figure.2 transmission spectrum of polarizer]](/uploads/editor/images/e-newsletter/2021/153/transmission-for-visible-polarizer.jpg)

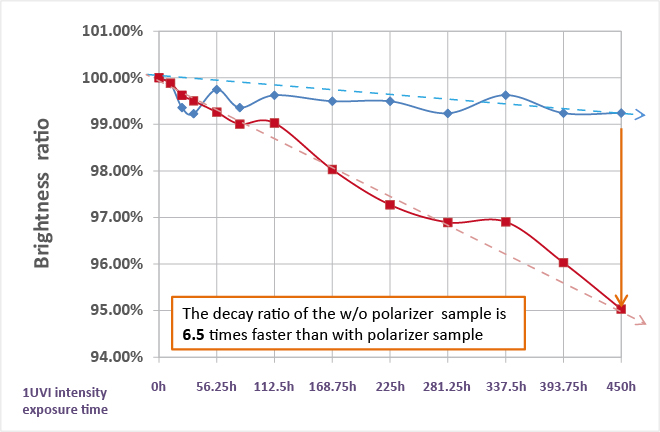

We designed an experiment to find out the polarizer’s ability of UV protection. We covered the half area of the OLED panel with polarizer, and the remaining area was not covered. Then we put the OLED panel into a UV chamber and measured the brightness decay rate for both areas. Please check the Figure.3. After suffering energy equaling to 1 UVI intensity expose 450 hours, the decay rate of the area covered by the polarizer ( blue line) is 0.76%, and the decay rate of area without any cover (red line) decayed 4.97%. It shows the polarizer can protect the organic material from UV damage.

In summary, OLED modules with polarizer can resist the damage of UV exposure effectively. It is recommended that the products which might be exposed to the sun should add polarizer to protect the OLED panel. Generally, there is no issue for handheld products with polarizer used in outdoor application. For outdoor fixed-position devices, it is recommended the modules should add a polarizer and a shed to avoid long-term direct sunlight to extend the OLED lifetime. Winstar is continuing do our best effort on development and production technology, our OLED modules have become the best display for long lifetime OLED modules and they already become the best choice for customer while adopting to use OLED display.

► Link to OLED Technology web page