Issue No. 164

- Contents

- 1) WEA009616B: 0.69" 96x16 Graphic OLED Module (COG+PCB Version)

- 2) WEO012864AB: 0.96" SSD1315 IC Dual Color Graphic OLED Display

- 3) WEA128128G: 1.12" 128x128 Graphic OLED Module (COG+PCB Version)

- 4) WEO012832N: 2.23"128x32 COG Graphic OLED Module

- 5) Winstar PMOLED module -The VFD replacement solution

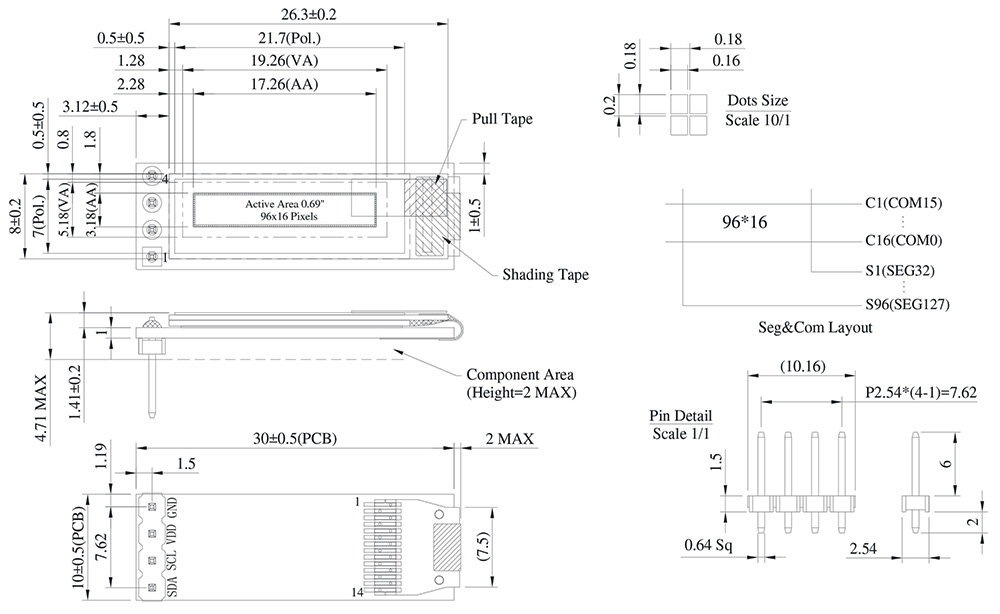

WEA009616B: 0.69" 96x16 Graphic OLED Module (COG+PCB Version)

WEA009616B model is a COG with PCB Graphic OLED module, diagonal size 0.69 inch, made of resolution 96x16 dots. WEA009616B model is the extension item of WEO009616B which has a PCB board on the module. This PCB board with four mounting holes and metal pins (2.54mm pinhole) is easy for customers to fix modules on their applications. WEA009616B module is built-in with SSD1306 IC; it supports I2C interface, 1/16 driving duty, the supply voltage of logic is 3.0V (typical value), and the current with 50% checkerboard display is 4mA @ 3.0VCC (for white color). The booster circuit has been designed on the PCB version, and the customer only needs to provide a set of VDD voltage to use.

This COG with PCB OLED module is suitable for portable devices, medical devices, meters, etc. WEA009616B module can be operating at temperatures from 30℃ to +70℃; its storage temperatures range from -30℃ to +70℃.

|

|

||||||||||||||||||||||||||||||||||||

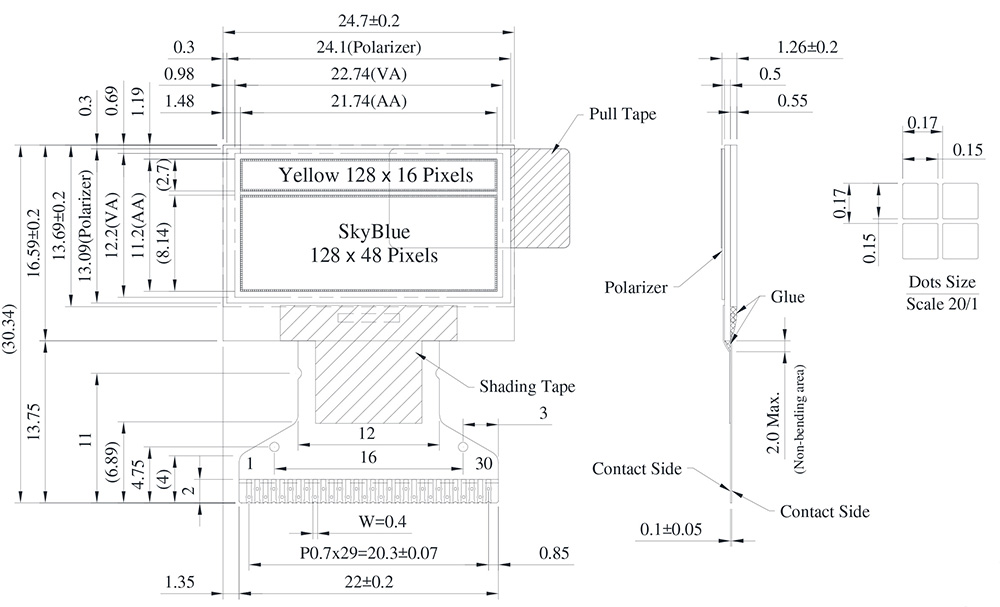

WEO012864AB: 0.96" SSD1315 IC Dual Color Graphic OLED Display

WEO012864AB is a 0.96" 128 x 64 Graphic OLED with a dual Color OLED Display; the standard color is yellow/sky blue only. It is a convenient way for customers to show lots of information in an easy-to-read display by using two separate colors (yellow and sky blue). This WEO012864AB Color OLED display module is built-in with SSD1315 IC; it supports 6800, 8080 parallel, 3 or 4-wire SPI, I2C interfaces; 1/64 driving duty. WEO012864AB model is an IC alternative solution to the WEO012864M model; WEO012864AB has a narrow border of the panel than WEO012864M, but the electrical characteristics and PFC pin definition are the same. Customers have to adjust the initial code only.

This Dual Color OLED module is suitable for medical devices, especially blood oxygen machines, etc. WEO012864AB module can be operating at temperatures -30℃ to +70℃; its storage temperatures range from -30℃ to +70℃.

|

|

||||||||||||||||||||||||||||||||||||

► Link to WEO012864AB web page

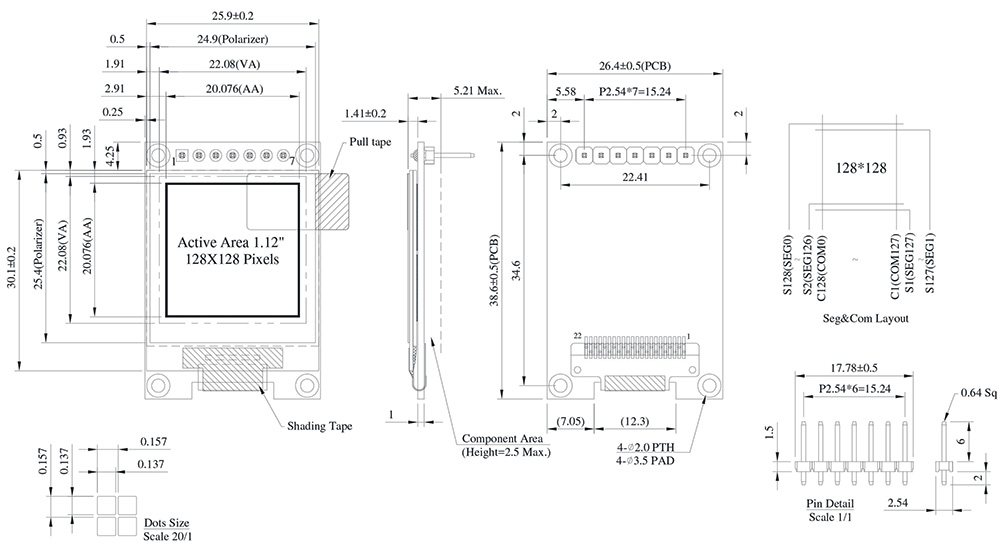

WEA128128G: 1.12" 128x128 Graphic OLED Module (COG+PCB Version)

WEA128128G model is a COG with PCB Graphic OLED module, diagonal size 1.12 inch, made of resolution 128x128 pixels. WEA128128G model is the extension item of WEO128128G which has a PCB board on the module. This PCB board with four mounting holes and metal pins (2.54mm pinhole) is easy for customers to fix modules on their applications. WEA128128G module is built-in with SH1107 IC; it supports 4-wire SPI interface, 1/128 driving duty, the supply voltage of logic is 3.0V (typical value), and the current with 50% checkerboard display is 65mA @ 3.0VCC (for white color). The booster circuit has been designed on the PCB version, and the customer only needs to provide a set of VDD voltage to use.

This COG with PCB OLED module is suitable for portable devices, medical devices, meters, etc. WEA128128G module can be operating at temperatures from 30℃ to +70℃; its storage temperatures range from -30℃ to +70℃.

|

|

||||||||||||||||||||||||||||||||||||

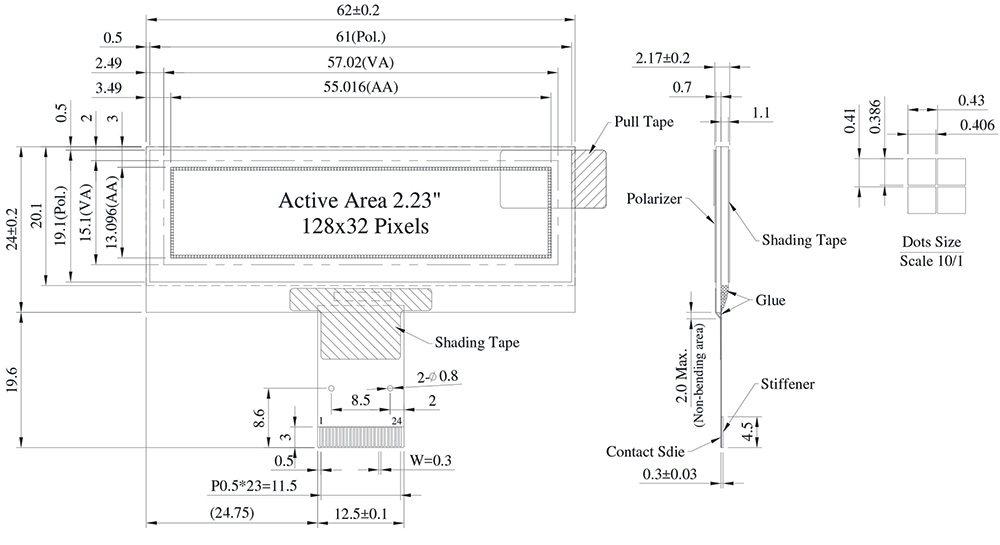

WEO012832N: 2.23" 128x32 COG Graphic OLED Module

WEO012832N is a 2.23” COG Graphic OLED display, made of resolution of 128x32 pixels. This module is built-in with SH1106 IC; it can be communicated via 6800 or 8080 parallel, 4-line SPI, and I2C interfaces; the supply voltage for display 12V (typical value), 1/32 driving duty, the supply voltage of logic is 3.0V (typical value), and the current with 50% checkerboard display is 15mA @ 12V VCC (for white color). The WEO012832N model is an IC alternative solution to the WEO012832A model; the electrical characteristics and PFC pin definition are the same. Customers have to adjust the initial code only.

WEO012832N model is ideal for smart home applications, m-POS, IoT systems, intelligent technology devices, energy systems, communication systems, medical instruments, EV charging, etc. This module can be operating at temperatures from -40℃ to +80℃; its storage temperatures range from -40℃ to +85℃.

|

|

||||||||||||||||||||||||||||||||||||

Winstar PMOLED module -The VFD replacement solution

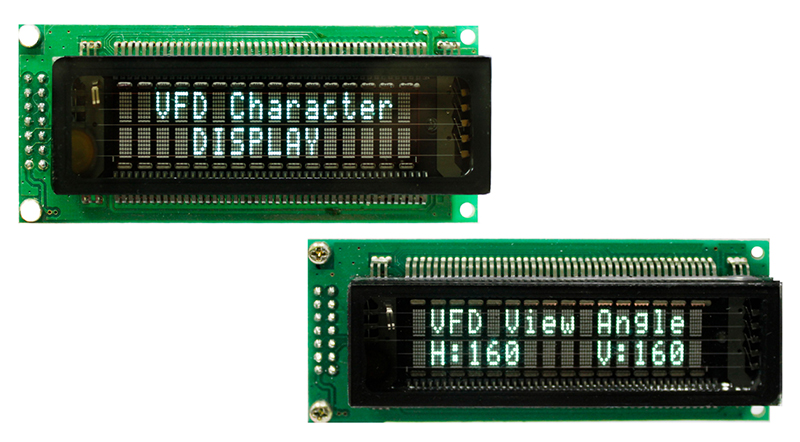

Vacuum Fluorescent Display (VFD) [Figure 1] is a display device with the same principle as a cathode ray tube; its main control device is a grid with controllable voltage. The electronics are accelerated to the anode under the attraction of the grid electric field. After hitting the fluorescent powder on the anode, they emit visible light with a specific wavelength distribution. By adjusting the voltage of the grid, the brightness of the vacuum fluorescent display can be adjusted. A plurality of vacuum fluorescent units are arranged in an array or a specific pattern, which becomes a VFD.

Figure 1: VFD Module

VFD was one of the important milestones in the development of displays and was widely used in various fields such as household appliances, DVDs, microwave ovens, office automation equipment, industrial instruments, and automotive instruments. However, with the development of display technology, various shortcomings of VFD have gradually surfaced. First of all, the most obvious is that the thickness of the VFD module is too thick [Figure 2].

With the development of various applications toward the lightweight, the thickness of the display module becomes the key factor.

Secondly, VFD mainly uses fluorescent powder to modulate the luminous color, and the display light color is single, such as green, yellow, and white.

In terms of contrast, the performance of VFD is not very good. A dark cover is usually added outside the VFD to improve the contrast, so the brightness decreases.

The power consumption of VFD is also relatively high because the electron beam of the VFD module hits the fluorescent powder of the vacuum tube. The energy will be converted into light and heat, respectively, and the energy conversion to light will be inefficient.

VFD is limited by material factors and is insufficient in a lifetime. Electrons strike the fluorescent powder to emit light; each time the electron strikes, the fluorescent powder will be damaged. After a period of use, the brightness of the VFD will decrease rapidly, and the chromaticity will also reduce.

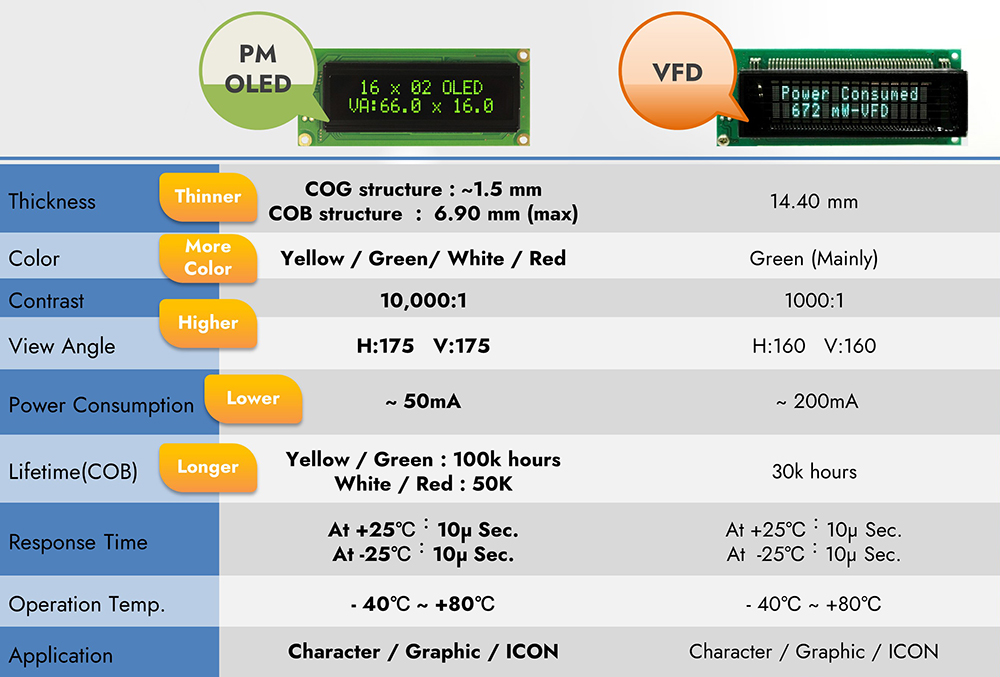

Figure 2: The Comparison of VFD modules and OLED modules

Based on the above disadvantages, the market is actively looking for alternatives to VFDs. Replacing VFD modules with OLED modules has many advantages, as shown in Table 1. Winstar provides PM-OLED module replacement solutions, which can effectively compensate for VFDs' weaknesses.

The most significant advantage is that the module's thickness can significantly reduce. Generally, the thickness of the VFD module is about 15mm, while the COG structure of the OLED module is only about 1.5mm, and the thickness is 10 times thinner than that of the VFD module. It's beneficial in the application of the product.

Furthermore, OLED modules have more colors available than VFDs. Because OLED is a self-luminous display, its contrast ratio is as high as 10000:1, which is about 10 times higher than the VFD module. The energy conversion efficiency of the OLED organic light-emitting layer is better, and the power consumption of the OLED module is much lower than that of the VFD module, only about 25% of the VFD module.

Finally, in terms of a lifetime [Note 1], OLED is much better than VFD. VFD is damaged due to the fluorescent powder's continuous bombardment of the vacuum tube wall by electron beams, and its brightness will decay rapidly. The estimated service life is about 30K. The lifetime of PM-OLED exceeds that of VFD in an all-around way. Yellow and green are about 100K hours, and white and red are about 50K hours, which is 1.5~3 times the lifetime of VFD.

Note 1: The definition of a lifetime is the time of OLED brightness decay to 50%

Table 1: PM-OLED vs. VFD parameter comparison

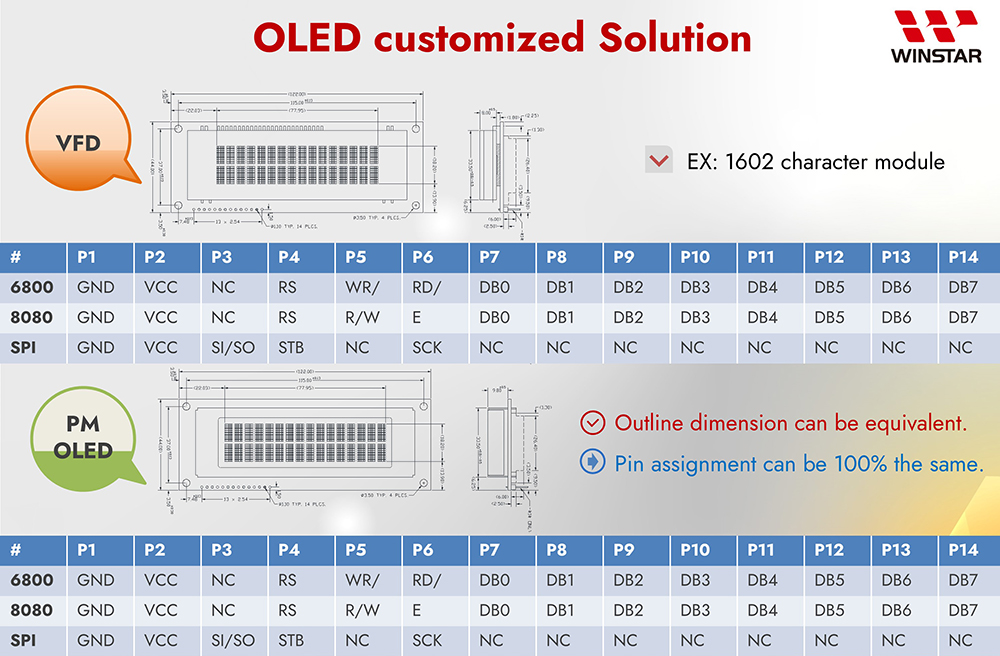

Many customers would like to use OLED modules to replace existing VFD modules, directly use them on existing product structures, and maintain the original module appearance, thickness, module interface, etc. (as shown in Figure 3).

Of course, this is no problem! Winstar can help customers customize PM-OLED modules that are the same as the original VFD modules. Regarding thickness specifications, spacers can be added to thin and light OLED modules to meet the same thickness as VFD. In terms of resolution, they can be maintained the same as VFD, and the module interface can ultimately be the same to achieve fast plug-and-play replacements!

Note 1: The definition of a lifetime is the time of OLED brightness decay to 50%

Figure 3: OLED Module Customized Solution Example